Filipino scientists from Ateneo de Manila University have developed a groundbreaking method to create transparent aluminum oxide (TAlOx), a material known for its extreme hardness and scratch resistance, by using tiny acid droplets and a small electric charge.

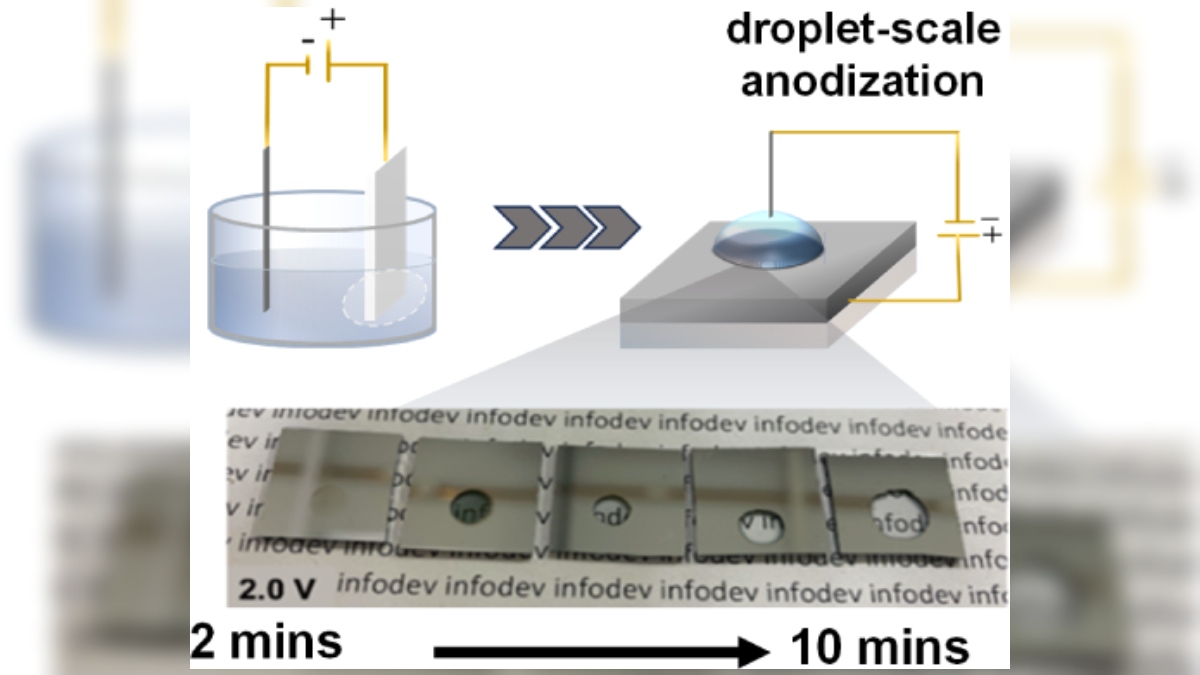

Traditional methods of making TAlOx require costly and complex processes involving high-powered lasers, vacuum chambers, or large amounts of hazardous acids. However, this new approach, called “droplet-scale anodization,” simplifies the process and makes it more environmentally friendly.

Instead of submerging entire aluminum sheets in acidic solutions, researchers applied microdroplets of acid onto small aluminum surfaces and used a low-voltage electric current—just two volts, slightly more than a household AA battery—to trigger the transformation. This technique relies on electrowetting, a process where an electric field alters a liquid droplet’s properties, allowing precise control over how the metal converts into a glass-like, transparent material.

The discovery could make TAlOx more affordable and widely available for use in touchscreens, optical sensors, solar panels, and ultra-durable coatings for vehicles and buildings. It may also advance miniaturized electronics by enabling the creation of insulating, transparent layers on a microscopic scale.

The study was published in Langmuir and co-authored by Marco Laurence M. Budlayan and Raphael A. Guerrero from Ateneo’s Department of Physics, along with Juan Paolo S. Bermundo, James C. Solano, Mark D. Ilasin, and Yukiharu Uraoka from the Nara Institute of Science and Technology in Japan.